Experience as the foundation – technology as the driving force

“In 1980 I invested in a used milling machine for production of cutting dies.” This is how Konrad Havlat started the success story of our enterprise. Although today’s machine fleet does not appear to be comparable in type and scope, each of the subsequent investments was based on the same philosophy: Assurance of the productive capacity as a provider of manufacturing services through investments in the future. Now we rely on state-of-the art technology from leading machine tool manufacturers and our decades of know-how in the production of precision parts.

Innovation is not a compulsion, it is a need.

Horizontal lathes

Highlight-Machine :

DMG Mori – CTX gamma 2000 TC

Powerful & process-optimised. Our CTX gamma 2000 TC machines enable a 6-side complete machining for the flexible manufacture of highly complex components. In combination with CNC automatisation, we manufacture your components in any batch size.

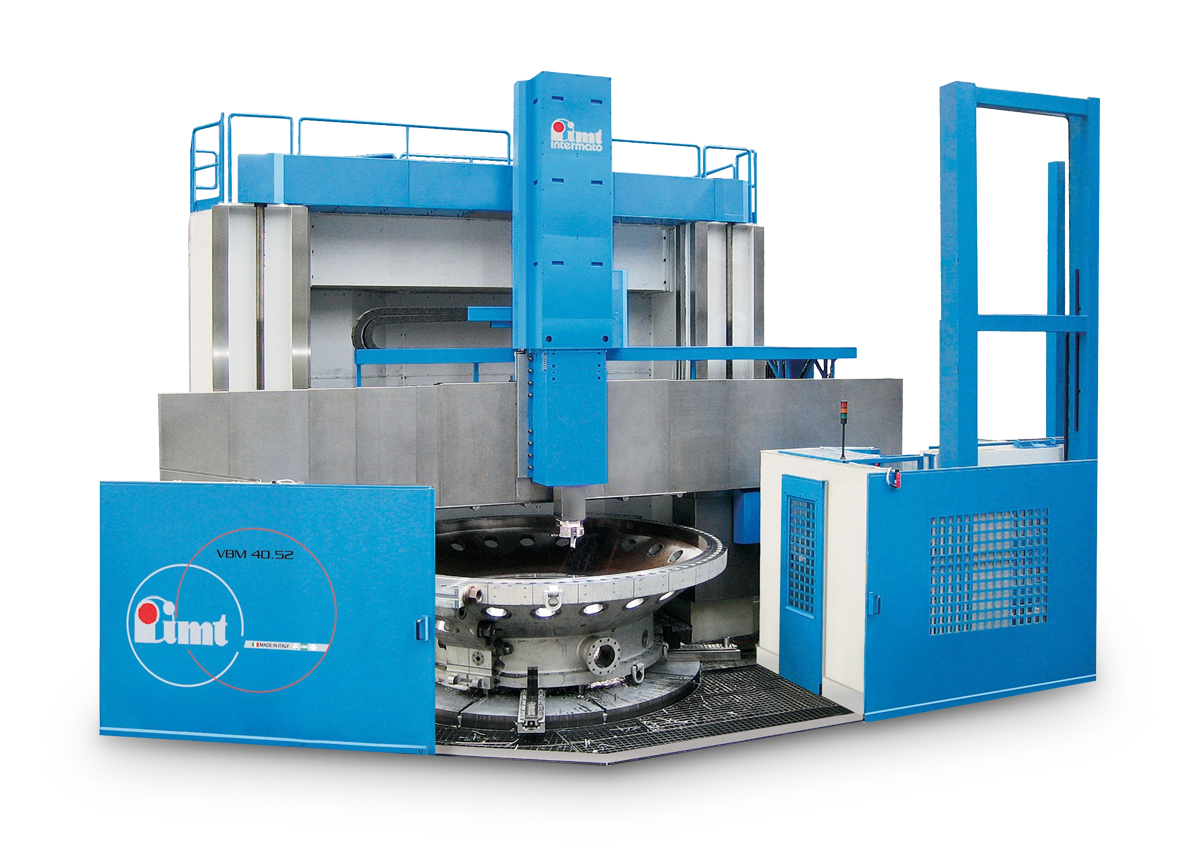

Vertical lathes

Highlight-Machine :

IMT Procast Line – VBM 40/52

Maximized. Turning on the VBM 40/52 is impressive – this is confirmed by workpieces with a diameter of up to 5,200 mm, a height of up to 3,000 mm and a weight of up to 25 t. Through a driven processing spindle, in addition to turning, milling and boring are also possible.

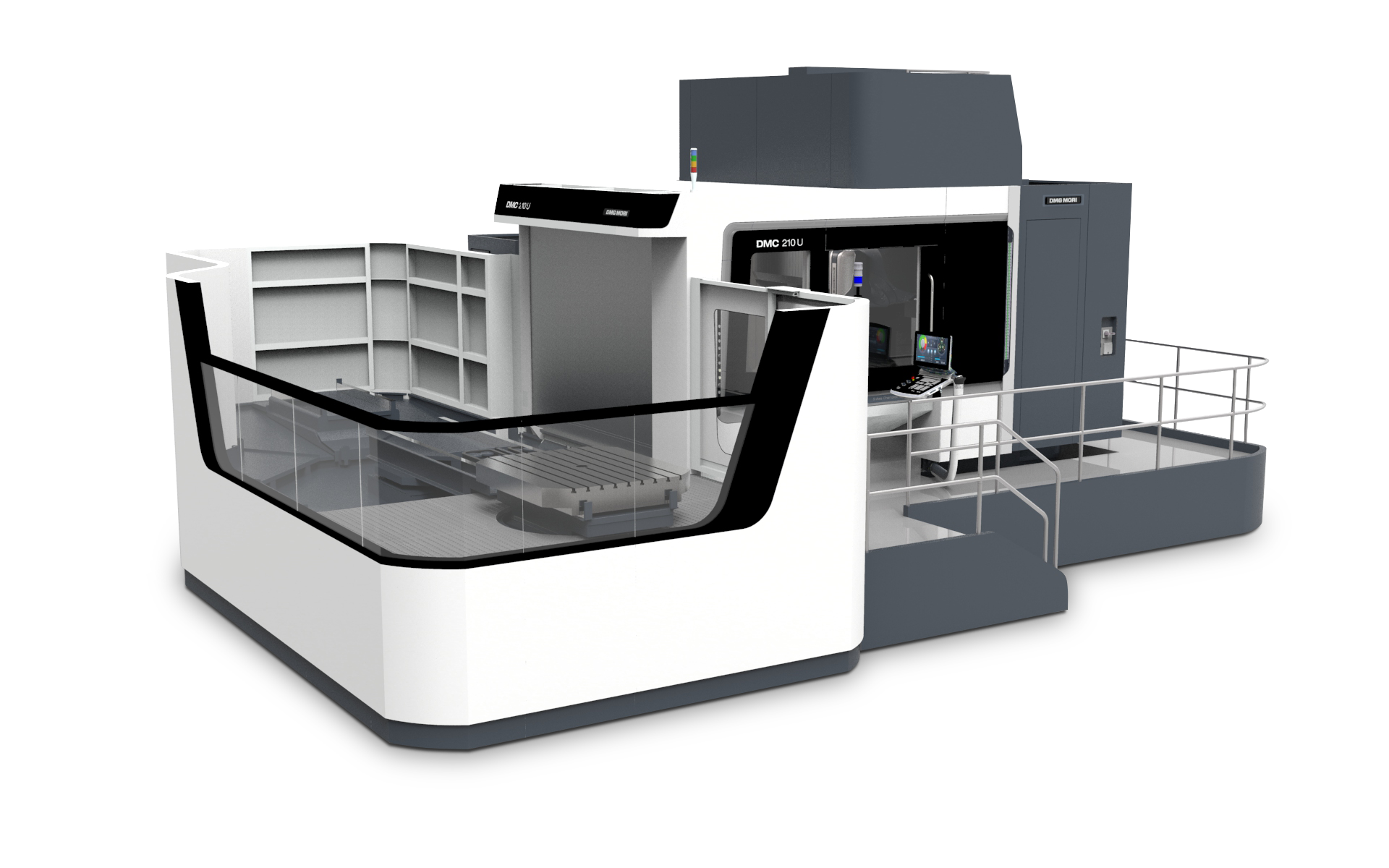

Milling machines

Highlight-Machine :

DMG MORI – DMC 210 U μ precision

High-precision milling. In an air-conditioned production environment, the DMC 210 U μ precision machine fulfils the highest demands in geometrical and positional tolerances. A particularly high level of efficiency is ensured by a wheel type magazine with up to 303 tools, the fivefold-pallet rotary storage unit as well as a powerful motor spindle.

Grinding machines

Highlight-Maschine :

Kehren – Ri 16-4

High-precision. With a maximum workpiece diameter of 1,700 mm our Ri 16-4 represents the highest level of grinding processing of our manufacturing. Equipped with a tool turret and an integrated measuring device, it combines flexibility and precision.

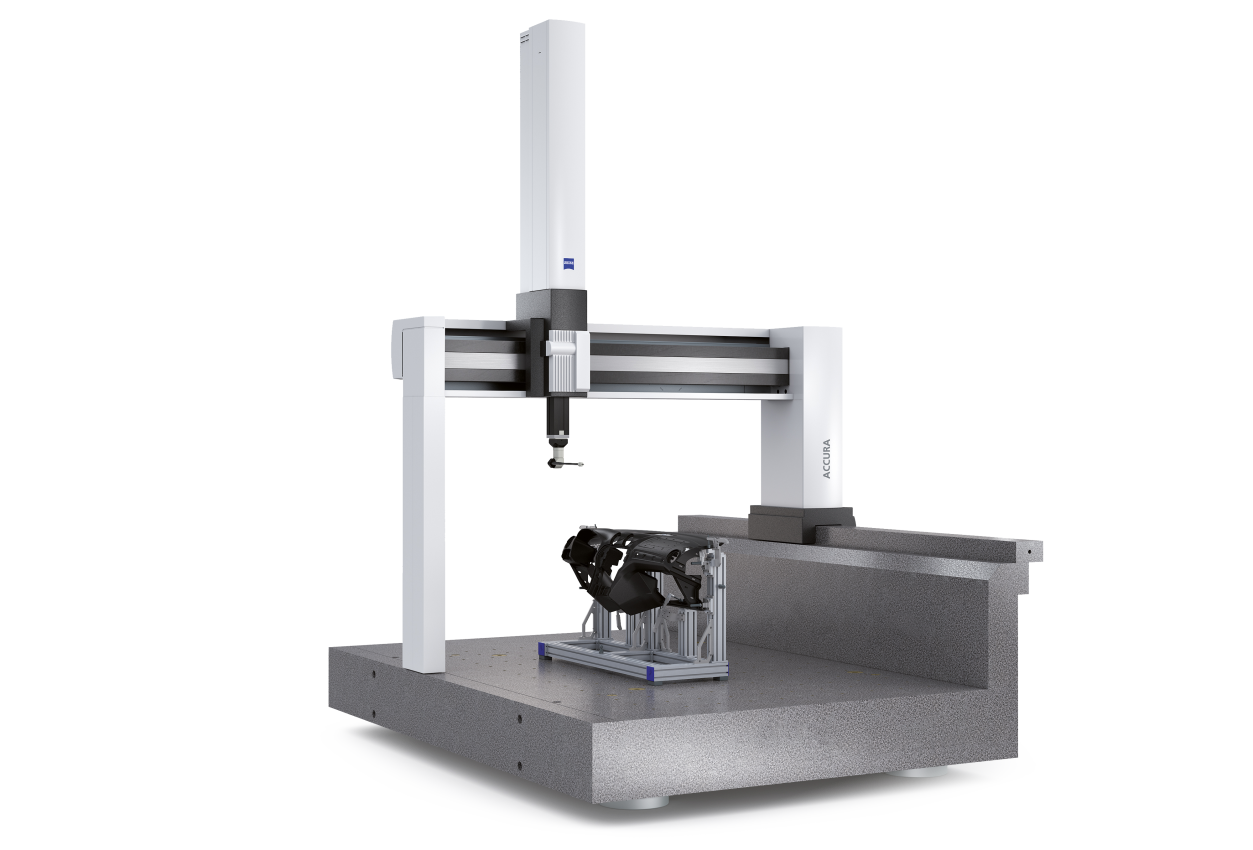

Measurement technology

Highlight machine :

Zeiss – Accura II

Exact. Measuring machines are a mirror of the manufacturing performance – and so is our Accura II. In spite of its high measuring volume, we can rely on measuring accuracy in all areas. Repeatability is a matter of course in this regard.

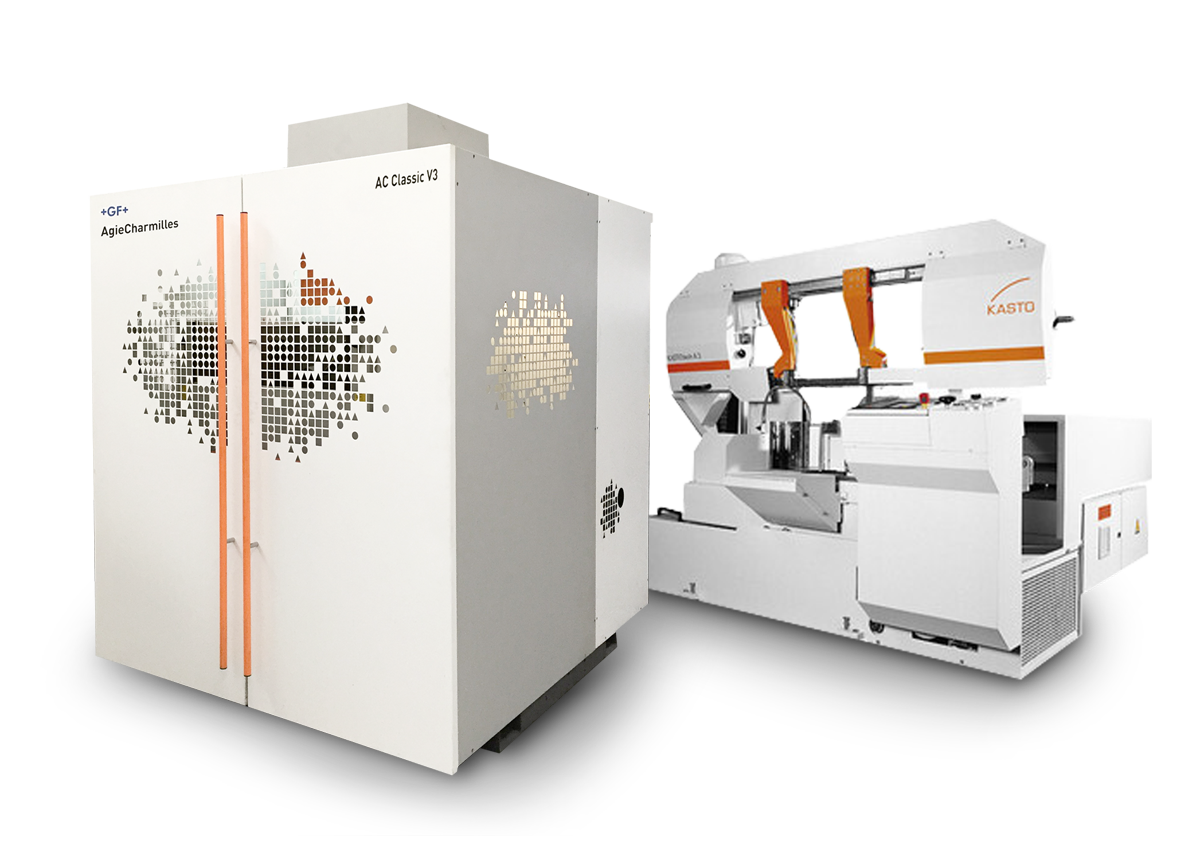

Additional services

Highlight :

Erode, Sawing, …

Flexible and versatile. In addition to classic machining we offer continuous wire EDM and die sinking of highly complex geometric shapes. Likewise, the production process supports economical manufacturing of such workpieces, as does our in-house cutting of unmachined parts, through straight-cut band saws and block band saws.