CNC milled parts | Milling technology | multi-spindle machining

Simple & highly complex CNC milled parts in small- and high volume production

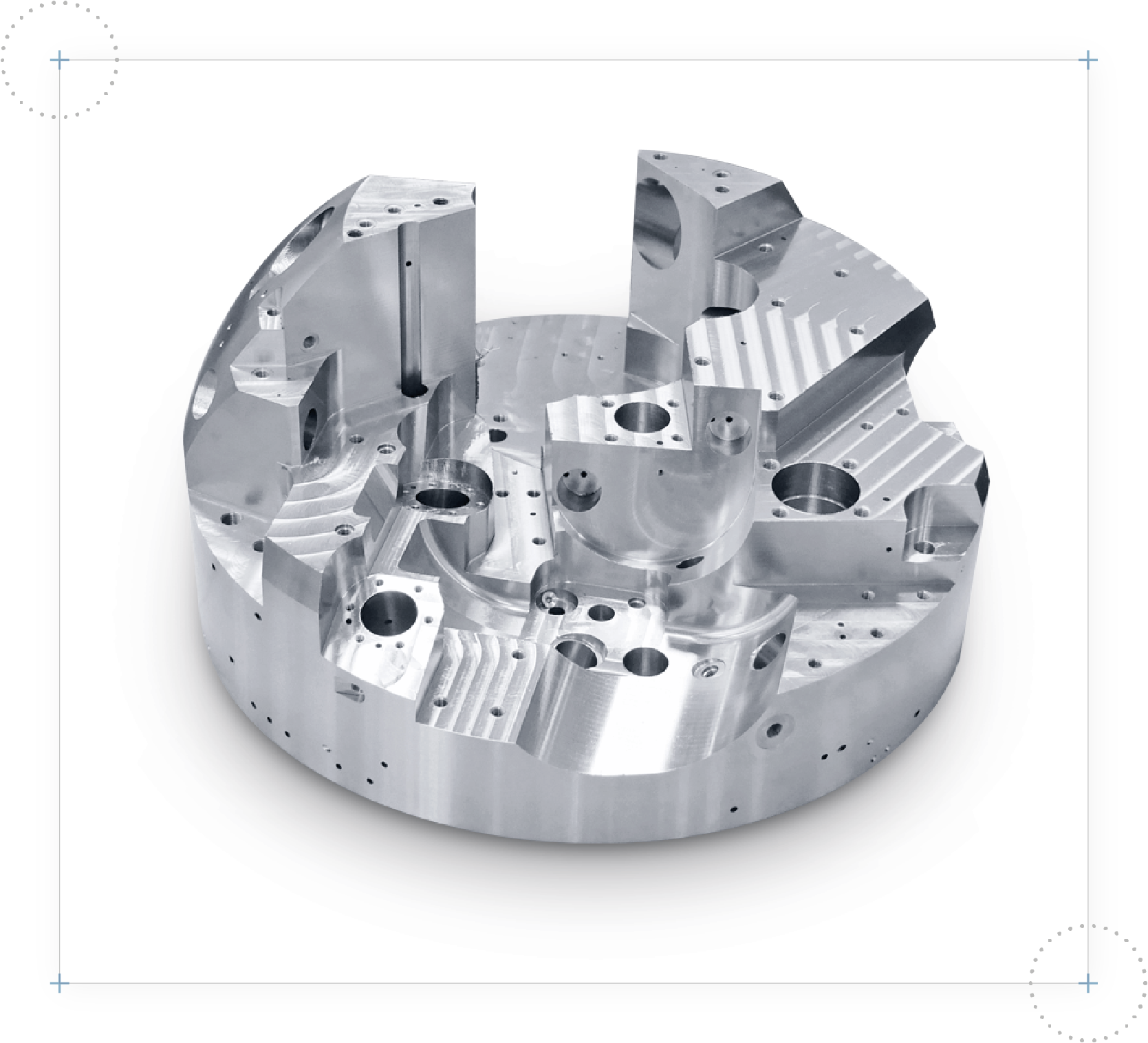

In the area of machining prismatic component geometries our machine fleet includes 29 modern CNC-mill-turn-centers in a variety of designs. Thus, we are able to flexibly and economically manufacture components in dimensions from 10 mm to 2,200 mm. Our 5-axis machining centers enable production of highly complex geometries, such as turbine blades and jig parts. In this regard precision is always the central focus. Depending on the component size, we manufacture to 5 µm tolerance specifications. Optionally, rotationally-symmetric elements are produced directly and without machine change on rotary tables of mill turn machining centers. The predominant use of pallet change and zero-point clamping systems reduces our throughput times to a minimum, for a maximum of efficiency.

HAVLAT – ACCLAIMED AND CERTIFIED

Commission CNC Milled parts from HAVLAT – your advantages at a glance

Installation-ready precision components

Scalable collaboration – from single parts to series

Extensive experience in implementation and consulting

Partial or total CNC processing

Diverse component dimensions 10 to 2,200 mm

Extensive range of materials

Heat treatment and surface treatment in cooperation

Certified quality and energy management

Get a free quote for your CNC milled parts!

We manufacture components in series – precisely and effectively

This is how job order production works at HAVLAT.

Our CNC milling technology in overview

- Multi-sided machining in one clamping cycle

- 5-axis simultaneous milling operation

- Flexible tool and pallet change systems

- Highly-efficient machining centers

- HSC machining to 40,000 rpm

- Tolerance compliance to 5 µm

Reference component: Grundkörper

CNC Milling machinery at HAVLAT

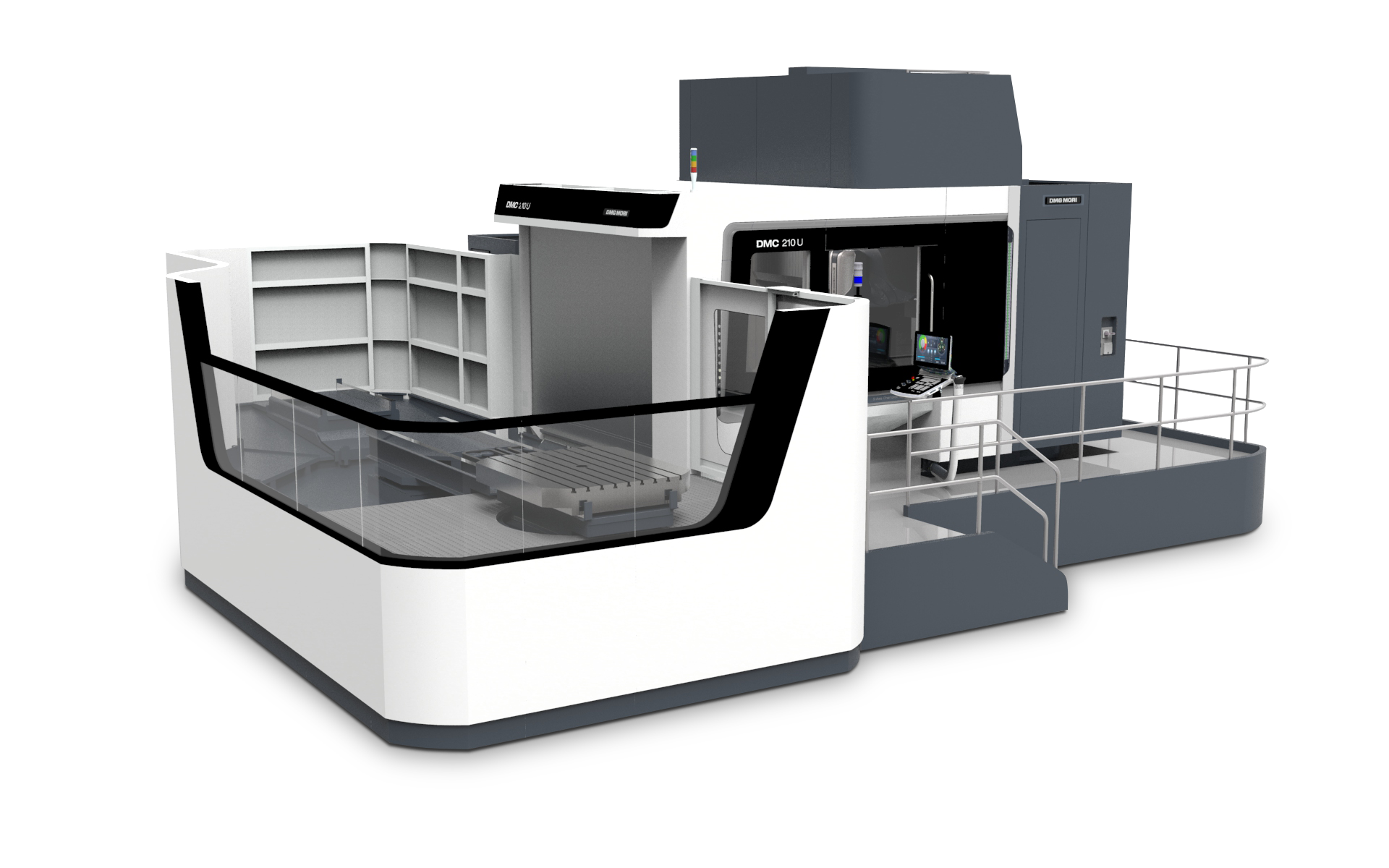

Our modern, powerful fleet of machines is at your service. Thanks to constant investment in the future, we are assured of our abilities as a CNC job order manufacturer and production service provider in general. We rely on the latest technology from leading machine tool manufacturers and our decades of experience to produce precision components. Why not join us?

Milling machines

Highlight-Machine :

DMG MORI – DMC 210 U μ precision

High-precision milling. In an air-conditioned production environment, the DMC 210 U μ precision machine fulfils the highest demands in geometrical and positional tolerances. A particularly high level of efficiency is ensured by a wheel type magazine with up to 303 tools, the fivefold-pallet rotary storage unit as well as a powerful motor spindle.