Precision requires quality. To manufacture complex, precision components, in addition to manufacturing expertise and state-of-the-art machine tools, we also need high-performance and ever-present quality assurance. Since 1996 HAVLAT has had a continuously certified quality management system in accordance with DIN EN ISO 9001. With more than 3,500 calibrated measuring and test equipment items, air-conditioned measuring rooms, as well a qualified staff we assure reliable precision and quality of your products. In this regard, the self-testing on the part of our machinists in all manufacturing stages is supported by a team of specialized measurement engineers. Thus, in reliable processes, we are able to implement the highest requirements imposed on dimensional and surface tolerances in manufacturing and quality controls.

Quality as expression of our competence

3D Measurement

Technology

- Five modern CNC-controlled 3D measuring machines in various sizes and with different equipment

- 3D measuring arm for flexible use

Manual Measurement

Technology

- A versatile portfolio of analog and digital measurement & test equipment

- Digital management of measurement equipment with test interval monitoring

Additional Measurement

Technology

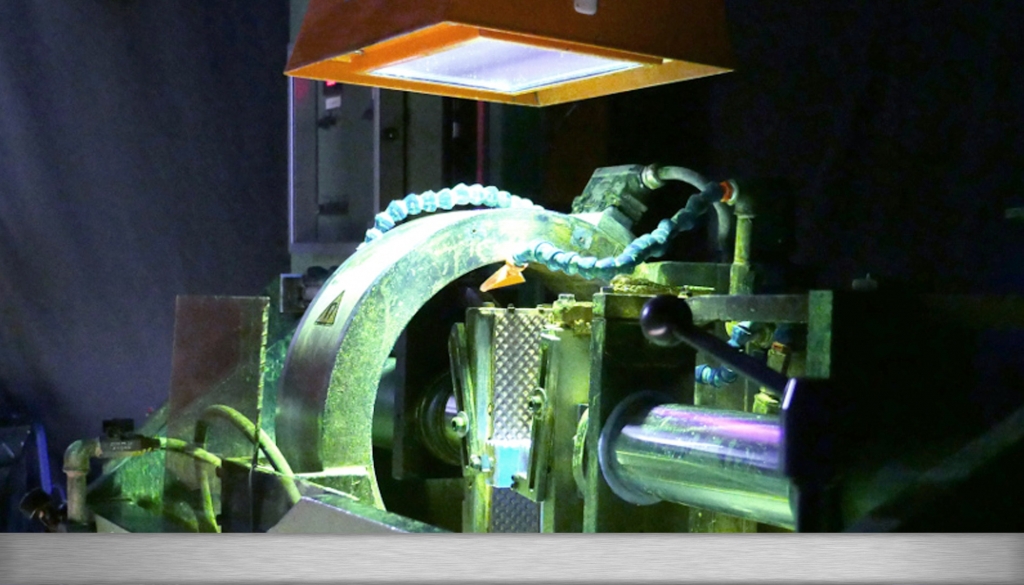

- Dynamic-plastic hardness measurement

- Roughness and contour measurement

- Magnetic powder crack test

Your advantages at a glance:

Modern CNC 3D measurement technology

Specialized measurement engineers

Separate and air-conditioned measuring rooms

A versatile spectrum of measurement & test equipment

Regular monitoring of measurement and test equipment

Quality controls in all manufacturing stages

Logging of all test measures